Absolute Error

Table of Contents

How to Find Absolute Error

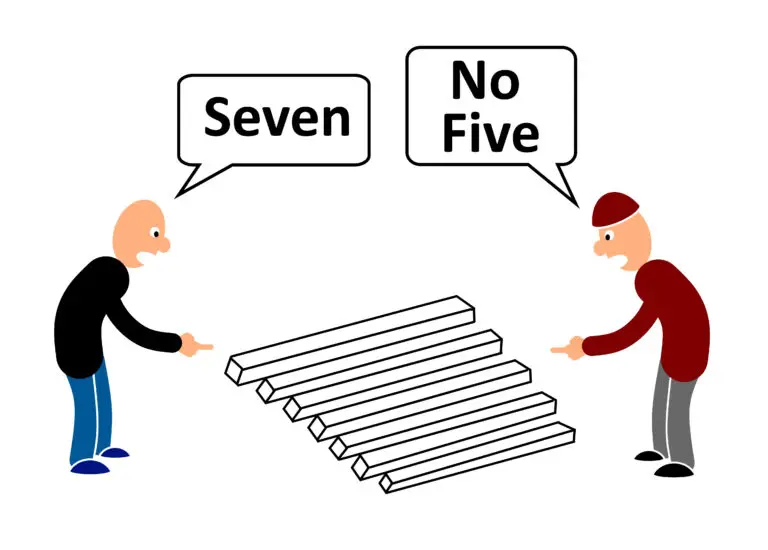

Absolute error measures the difference between the actual or estimated value of a quantity and its true or established value, showing the size of the error without regard to its direction, whether positive or negative.

To calculate the absolute error, you find the absolute value of the difference between the observed (or measured) value and the true (or accepted) value. Mathematically, this is expressed as:

The formula for absolute error is:

AE = | Observed Value – True Value |

Overview

Absolute error is important in fields like science, engineering, and statistics as it provides a straightforward way to understand the accuracy of measurements and calculations, indicating how much the measured or calculated values deviate from the actual values.

Engineering and Construction: Precision is paramount in engineering and construction projects, where even small errors can lead to significant consequences. Absolute error is used to determine the accuracy of measurements related to the dimensions of structural components, alignment of elements, and adherence to design specifications. Ensuring that these measurements are as close as possible to the intended values is crucial for the structural integrity and functionality of the construction project.

Science and Research: Absolute error provides a way to evaluate the reliability and precision of experimental data in scientific and research activities. By comparing measured values with accepted standards or theoretical predictions, researchers can ascertain the validity of their experiments and the accuracy of their measurement techniques. This comparison is essential for scientific studies, as it helps identify potential discrepancies and refine methodologies.

Quality Control: In the manufacturing sector, maintaining the consistency and quality of products is vital. Absolute error is used to verify the dimensions and specifications of manufactured parts, ensuring they meet the required standards. It is also employed in assessing the calibration and accuracy of measuring instruments, guaranteeing that they provide precise readings. This level of scrutiny helps minimize defects, reduce waste, and improve the overall quality of products.

Example

Suppose you are measuring the length of a rod, and the true length is 100 centimeters. If your measurement indicates 98 centimeters, the absolute error would be:

AE = | \text{Observed Value} – \text{True Value} |

AE = | 98 cm−100 cm | = 2 cm

So, the result in this case is 2 centimeters. It represents the magnitude of the difference between the observed value and the true value without considering the direction (whether the observed value is greater or smaller than the true value).

Absolute Error Calculator

Instructions: Input observed and true values to get the Absolute Error.

Related Links

Absolute Value

Type I Error

Type II Error

Chance Error